Thank you for Subscribing to Food Business Review Weekly Brief

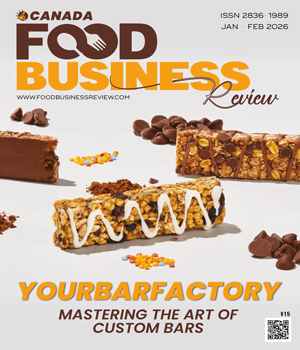

Global snack markets have evolved, and the demand for allergen-free, gluten-free, kosher, and peanutfree bars is at an all-time high. Many manufacturers and retailers want to enter this market but struggle to meet the strict dietary standards these products require. The investment is significant, and mastering both the process and the formulation of a greattasting recipe is easier said than done. But what if any company could market such specialty bars in-house without the burden of building its own manufacturing facility? For the past 25 years, Yourbarfactory has met these exact requirements without compromise and continues to thrive. Based in Quebec, Canada, the company specializes in manufacturing high-quality allergen-free bars—nut-free, peanutfree, and gluten-free—for private labels, custom brands, and international markets. CEO Martin Joyal sums it up simply: “We are not a brand ourselves, but we are the backbone behind every brand.” From retail giants to ambitious startups and well-established businesses, Yourbarfactory partners with customers to deliver cost-effective, large-scale solutions. To meet diverse production needs, the company operates three distinct production lines: one for highvolume, large-scale orders; another for standard production runs; and a dedicated line for start-ups and smaller batches. This level of flexibility and scalability gives Yourbarfactory a clear competitive edge. “We are giants in niche markets, yet smaller and more flexible players in larger ones,” adds Joyal, highlighting the company’s unique position in the industry.

Top Coffee Equipment Distributors And Services Provider in Canada 2026

ECM Espresso Coffee Machines Company is Western Canada’s longest-standing distributor of commercial espresso equipment. For more than 55 years, the company has shaped the way coffee is brewed and served across the region, collaborating with foodservice operators to introduce Italian espresso standards to Western Canada’s commercial coffee landscape. Through its partnership with Nuova Simonelli, an Italian manufacturer of commercial espresso machines, ECM introduced equipment built for continuous commercial use, including Nuova’s higher-end Victoria Arduino machines. Known worldwide for handcrafted machines engineered for longevity, thermal stability and consistent performance in high-volume environments, Nuova Simonelli’s technology allowed Italian espresso standards to hold up in real service conditions, where reliability and repeatability matter as much as craftsmanship. Reliability at the point of service depends on reliability behind the scenes. From its 15,000-square-foot facility on the Vancouver Burnaby border, ECM maintains nearly $2 million in locally stocked inventory, including machines, parts and accessories. Keeping critical components on hand—rather than relying on overseas lead times—allows the company to respond quickly when equipment issues arise. During peak service periods, that immediacy becomes decisive. Faster access to parts reduces downtime, protects throughput and helps operators maintain staffing flow and customer experience when even brief interruptions can ripple through operations. “It’s this readiness that became especially visible during COVID-19. While many businesses paused operations, our service department remained active because clients were still running and still needed equipment support,” says Danny Bresciani, sales manager. ECM has remained family-led since its founding, with successive generations working side by side. Founders Tom Bresciani and Remo Bresciani were café owners themselves, and their experience shaped the business from the outset. They understood how difficult it could be to source commercial machines and how delayed access to replacement parts could turn routine maintenance into lost revenue..

Gourmet Products Importer and Distributor in Canada

Acema Importations meets Canada’s growing appetite for refined international cuisine with an expansive and thoughtfully curated portfolio. From pantry staples to specialty indulgences, its lineup includes artisan pastas, premium olive oils, aged balsamic vinegars, cookies, confections and a whole lot more. Eighteen years ago, François Bibeau and Marc Fortin acquired Acema from its original founder, who launched the brand in 1992. Since then, the team has traveled the world in pursuit of the finest culinary offerings. Known for its innovation and steady introduction of new products, Acema has evolved into one of the nation’s most trusted names in gourmet imports. Today, it sources from over 10 countries, bringing global flavours together under one roof. Every decision is driven by curiosity, intuition and a passion for discovery, resulting in a collection of exceptional finds that surprise and delight both retailers and consumers. At the heart of this evolution is a service model defined by consistency, care and collaboration. Acema’s reputation for reliability has made it a go-to partner across various retail formats. From the moment an order is placed to when it’s delivered, every team member is focused on exceeding client expectations. Sales representatives follow a consistent visit schedule, enabling clear communication and proactive inventory management. Retailers especially value the professionalism and predictability this approach delivers, particularly when handling large, complex orders that require meticulous attention, often one case at a time. “Our goal has always been to ensure that once Acema delivers a customer, we want to increase the number of products delivered to that store. This has been an important part of our organic growth,” says François Bibeau, president.

CXO INSIGHTS

Implementing Technological Advancements in Food Industry

Kitty Pat, Director of Quality Assurance, Bento Sushi

For People and The Planet: How Olipop Commits To Building A Better Future

Elric Centers, Sustainability Manager, OLIPOP PBC

Integrating Innovation and Practicality for Sustainable Packaging Solutions

Julia Lodi, Procurement Specialist - Packaging, Nature’s Path

Fueling Culture through Everyday Dining Experiences

Jason Olinik, Vice President, Dining, Continental

From Photography to Strategy: Designing Memorable Dining Experiences

Huy Tran, National Marketing Director, Aburi Restaurants Canada

IN FOCUS

The Science and Strategy Behind Canada's Next-Gen Allergen-Free Bars

Canada’s snack bar market is innovating with allergen-free, clean-label ingredients and advanced manufacturing to deliver superior taste, texture, and nutrition, making “free-from” snacks mainstream and indulgent.

Regulatory Harmony and Sustainable Growth in Canada's Coffee Equipment Economy

Canada’s coffee equipment distribution industry drives a $28B market through strict technical standards, regulatory alignment, ethical sourcing, and circular design, fostering sustainability, innovation, and equitable growth nationwide.

EDITORIAL

Building Resilient and Sustainable Food Operations

Coffee equipment distributors are evolving into long-term service partners rather than simple suppliers. Allergen-free bar manufacturers are building credibility through disciplined production and rigorous risk control. Gourmet product importers and distributors are strengthening sourcing and logistics to protect product integrity across markets. Together, these segments reflect a shift toward operational strength as the defining competitive advantage.

Key technology trends driving expansion include remote equipment monitoring, controlled production segregation systems, and demand-forecasting software. Remote equipment monitoring improves coffee equipment distribution and service by enabling predictive maintenance and reducing downtime. Controlled production segregation systems strengthen allergen-free bar manufacturing by minimizing cross-contact risk while supporting compliant scale. Demand-forecasting software enhances gourmet product importing and distribution by optimizing sourcing, inventory management, and product freshness.

This edition of Food Business Review Canada explores how reliability and supply-chain control are redefining positioning across the country’s specialty food and beverage landscape.

It features thought-leadership articles from industry leaders, including Huy Tran, national marketing director at Aburi Restaurants Canada, who examines how education-led marketing and community-focused dining experiences shape brand consistency and guest engagement across multi-brand restaurant portfolios. Guillaume Couture, quality assurance manager at Kerry’s Ste-Claire facility, discusses safeguarding food safety and quality in nutritional beverage production. He highlights how integrated RD&A collaboration, preventive quality systems, and extended shelf-life processes protect nutritional integrity while meeting strict regulatory standards.

We hope this edition showcases the innovations driving smarter, more sustainable, and higher-quality practices across food production, processing, and service, supporting stronger performance and lasting growth.