Thank you for Subscribing to Food Business Review Weekly Brief

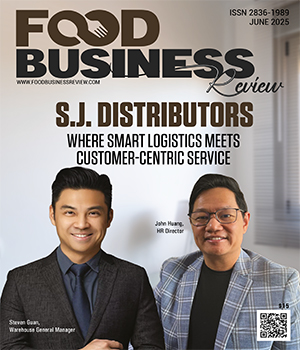

In the heart of the wholesale food distribution industry, where reliability and efficiency make or break businesses, S.J. Distributors has carved out a reputation for excellence. More than just a supplier, the company has built its foundation on three key pillars: delivering high-quality products, offering unmatched customer service, and giving back to the community. S.J. Distributors is not just about moving products from warehouse to restaurant kitchens. It’s about relationships— understanding each customer’s unique needs, adapting to industry challenges, and going the extra mile to ensure businesses thrive. More than Just a Supplier Walking into S.J. Distributors’ warehouse, you can feel the energy. Pallets of frozen meats, seafood, and dry goods are stacked high, ready to be delivered to a diverse customer base. From small mom-andpop restaurants to large chain stores, each client has specific needs—and S.J. Distributors prides itself on meeting them all.

Buyer’s Choice For Oils, Fats and Release Agents 2025

Since 1948, Colony Products has been more than just a manufacturer of oils, fats, and release agents—it has been a trusted partner in progress for companies seeking excellence, consistency, and innovation. A family-owned business spanning four generations, the company has built its reputation on a commitment to food safety, customization, and customer-first service. Today, under the leadership of President Michelle Graham, Colony Products is redefining what it means to be a reliable and forward-thinking supplier in an ever-evolving industry. What distinguishes Colony Products is its long-standing presence and its ability to adapt, pivot, and thrive amid changing market conditions. In a landscape marked by shifting consumer preferences, supply chain unpredictability, and increasing regulatory scrutiny, the company stands out by addressing modern challenges with agility and foresight. Graham succinctly captures this ethos: “We’re small enough to be flexible, quick, and personal—but large enough to have excellent purchasing power and a strong network of suppliers.” Commitment to Custom Food Safety Solutions One of the key concerns facing Colony Products’ customers today is navigating the complex terrain of food safety and ingredient transparency. With growing awareness around sustainability and clean labeling, brands are being pushed to seek products that are nutritionally aligned with consumer expectations, ethically sourced, and environmentally sound. Colony Products’ deep integration within the U.S. manufacturing landscape provides its clients with a rare blend of security and agility. Most of its ingredients are sourced from domestic suppliers, which gives clients peace of mind in a world where global supply chain disruptions are increasingly common. Colony Products is GFSI-certified and has consistently received top-tier ratings—including AA and AA+—even through unannounced audits, a testament to its relentless commitment to quality and compliance. However, certifications alone do not define the company. Its ability to translate high standards into actionable, customer-specific solutions makes Colony an indispensable partner.

Top Conveyor Ovens Manufacturer 2025

What will the foodservice industry look like five years from now? This question is what makes David Shave tick. As the president of Middleby Marshall, Shave helps restaurant operators tackle current challenges while preparing for future industry shifts. With rising labor costs, sustainability concerns and evolving consumer demands, Middleby Marshall, an equipment manufacturer known for conveyor oven innovations, empowers operators to maximize revenue from every square foot of kitchen space, with an eye toward what’s next. “I’ve always looked at the restaurant industry almost like the real estate industry—how much revenue can you generate from that fixed asset?” says Shave. To that end, Middleby Marshall delivers technology-driven solutions that reduce energy use and streamline workflows, while enhancing food quality and consistency. Its hallmark innovation has long been its impingement ovens, which use high-speed, targeted air to ensure even cooking and rapid throughput. These ovens include features like the Energy Eye and One Touch systems that automatically detect idle time and reduce power consumption, providing significant energy savings without sacrificing readiness. But impingement isn’t the only tunnel-based technology driving performance. Middleby Marshall’s LongWave ovens, its rebranded CTX platform, use long-wave infrared to deliver high-intensity, dry heat. Reaching temperatures up to 1200°F, the LongWave ovens enable automated char-grilling, ideal for steaks, chicken and burgers. Rather than relying on high-velocity air, LongWave ovens apply focused radiant heat to replicate the sear and finish of a traditional charbroiler. This approach allows for vertical cooking, reduces the footprint required in the kitchen and minimizes excess heat in the environment. Operators benefit from lower HVAC demand, streamlined workflows and greater consistency—without the need for constant staff supervision or large linear grill setups. Both the platforms reflect Middleby Marshall’s philosophy of “perfection at every pass”—not just in food consistency, but across service, training and manufacturing. Whether it’s impingement for high-volume throughput or LongWave for delivering char-grilled finishes in compact kitchens, each system is tailored to meet diverse operator needs, balancing performance with price sensitivity.

CXO INSIGHTS

Inventory Management and Strategic Planning

Larry Williams – Chief Supply Chain Officer at Biscuitville Fresh Southern

Stabilizing Supply Chain Disruption by Building a Lean Organization

Olawale Ojo, Senior Global Lean Director, Griffith Foods

Adapting To Seasonal Changes: Chef-Driven Menus and Agriculture Supplier Offerings

Chef Chris Aquilino, Chief Culinary Officer, Elior North America

Shaping Strategic Alliances to Drive Market Expansion

Justin Miklos, Vice President of Strategic Channel Development, The Middleby Corporation

Engineering Leadership in Advanced Manufacturing Operations

William Samayoa, Plant Engineering Manager, JBS USA

IN FOCUS

EDITORIAL

How Technology is Powering The New Food Chain

At the center of this shift is the warehouse—once a static holding space, now a precision-driven hub of innovation. Equipped with automation, real-time data analytics and temperature-controlled systems, today’s warehouses orchestrate the movement of ingredients and finished goods with speed, accuracy, and transparency. From warehouse floors to cold-press facilities to smart ovens, the entire system is being reimagined—powered by technology, transparency and tighter producer-to-consumer links.

Until recently, most oils were processed with high heat or chemical solvents that stripped away their best qualities. Now, cold pressing and supercritical CO₂ extraction preserve flavor, aroma and nutrients—keeping the product close to its raw form. For consumers seeking clean, minimally processed products, that matters. Producers are responding—not just with better oils, but with better ways to deliver them. E-commerce and direct-to-consumer models bring more personalized service, faster delivery and greater sourcing transparency.

Meanwhile, cooking tech is transforming food prep. Conveyor ovens—once valued for speed—are getting smarter. Advanced controls, real-time monitoring and energy-saving modes now optimize cooking while cutting energy use. Models that shift to low power when idle support sustainability and cost savings.

Driven by these trends, the Food Business market is projected to reach approximately US$9.43 trillion in 2025, growing at a compound annual growth rate of 6.41 percent.

This Food Business Review brings thought leadership articles from Trisha McRoberts, Corporate Vice President / Chief Procurement Officer, at Golden State Foods, who emphasizes that innovation, strategic procurement, and empowered teams are key to supply chain resilience in a shifting global landscape. Additionally, William Samayoa, Plant Engineering Manager at JBS USA, emphasizes that proactive maintenance, continuous improvement and advanced automation are key to plant modernization and efficiency.

This edition features the Wholesale Food Supplier of the Year 2025, Organic Oil Products of the Year 2025 and Top Conveyor Ovens Manufacturer 2025, we hope you find the right partner to meet your organization’s needs. Let us know your thoughts!