Thank you for Subscribing to Food Business Review Weekly Brief

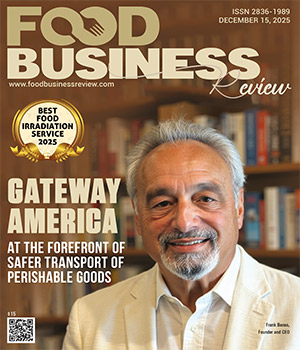

From oysters pulled from the Gulf of Mexico to mangoes ripened in South America and blueberries harvested in the Pacific Northwest, perishables make a long journey through ports, warehouses and inspection lines before reaching consumers. Changes in temperature or the slightest contamination can be the difference between fresh cargo and a rejected shipment. For years, the industry relied on chemical fumigation to manage these risks, most often using methyl bromide. It worked, but at a cost. The chemical’s ecological impact, particularly on the ozone layer, has long been a concern. With growing awareness of environmental sustainability, the industry is turning toward safer, cleaner alternatives—led by Gateway America. It is the first U.S. company built solely around phytosanitary irradiation. The scientific process uses precisely measured ionizing radiation to neutralize pests and pathogens while keeping food clean, safe and residue-free. Targeted irradiation eliminates E. coli, salmonella and listeria. This method of replacing chemical fumigation has been validated by the U.S. Department of Agriculture (USDA), and the World Health Organization and other global regulatory authorities. “Hospitals and laboratories have used irradiation for sterilization for decades,” says Frank Benso, founder and CEO. “We have been able to successfully adapt a proven medical process for food, and turn it into an agricultural solution that aligns with global food-safety standards.” Replacing Fear with Clarity People often associate radiation with risk, but Gateway America focuses on generating awareness to replace fear with understanding. “The reality is we’re all exposed to radiation daily, from sunlight to office lighting. In controlled, low doses, irradiation is safe, effective and a logical alternative to chemical fumigation,” explains Benso. That shift in understanding matters because irradiation isn’t just a safer process; it’s a smarter one. It preserves food quality, reduces chemical dependence and aligns food safety with environmental responsibility. Streamlining inspection and clearance at ports nationwide helps move goods faster and more efficiently from coast to coast.

Commercial Food Service Equipment Repair Services

In the restaurant business, a well-functioning kitchen is the backbone of success. When equipment breaks down, every minute counts. That’s where Elite Kitchen Services (EKS) steps up. Founded by Adam Roberts, EKS is built on a simple but powerful idea: to provide restaurant owners with a one-stop solution for kitchen equipment repairs, maintenance, and installations. Instead of dealing with multiple vendors for different issues, restaurant owners can rely on EKS to handle everything—from hot-side cooking equipment to refrigeration, HVAC, exhaust systems, and even minor plumbing and electrical work. “I wanted to create a company where restaurant owners didn’t have to call five different service providers to fix their kitchen,” Roberts explains. “With EKS, they make one call, and we take care of everything.” A Full-Service Approach to Kitchen Maintenance EKS isn’t just about repairs—it’s about keeping restaurants running smoothly and efficiently. The company offers preventive maintenance to help businesses avoid costly breakdowns and unexpected downtime. If an issue does arise, EKS technicians are trained to diagnose and repair both hot-side and cold-side equipment, ensuring clients don’t have to wait for a specialist to be available. Roberts has always believed that having highly trained technicians is key to providing top-tier service. “I don’t want a team where one guy only knows refrigeration and another only knows ovens,” he says. “I want every technician to be able to work on everything.” While some specialization is inevitable, EKS ensures that its team is cross-trained so they can handle a wide range of equipment and minimize delays for customers. Beyond repairs and maintenance, EKS also sources and installs commercial kitchen equipment. The company has the capability to order appliances, inspect them at its warehouse, and deliver them directly to clients. This hands-on approach gives restaurant owners peace of mind, knowing their equipment is installed properly and ready to perform.

CXO INSIGHTS

Alternative Proteins, Enabling Purposeful Eating For New Generations

Dina Fernandez, Global R&D Director, Alternative Proteins, Archer Daniels Midland (ADM)

Advantages of Food Delivery Services for Restaurants

Landon Wells, Manager of Training and Development, Slim Chickens

Five Keys to Successful Leadership

Jim Beauregard, Director of Research & Development, The Mennel Milling Company

Mitigating Risk by Simplifying Food Safety Reports

Sharon Maloney, Food Safety and Quality Manager, Portillo’s Hot Dogs, LLC

Food Safety Culture

Steve Hammond, Food Safety & Quality Assurance Professional, Sandridge Crafted Foods

IN FOCUS

Global Food Security and the Rise of Irradiation Logistics

Food irradiation is a vital technology for food safety, evolving through specialized models for fresh produce, meat, and spices to meet global demand for safer, high-quality products.

Co-Manufacturing as the Growth Engine for Hazelnut Chocolate Spreads

Co-manufacturing empowers hazelnut spread brands with cost flexibility, rapid innovation, and supply chain efficiency, enabling agile growth, premium products, and faster response to evolving consumer trends.

EDITORIAL

Rethinking Safety to Unlock Better Formulations

Producers are increasingly turning to advanced, non-chemical treatments that neutralize pests and pathogens without affecting food texture or flavor. These tools stabilize entire supply networks. When shipments move across borders without fumigation delays or spoilage risk, exporters gain predictable timelines and ship fruit and vegetables at peak ripeness.

At the same time, greater control over safety is accelerating the shift toward simpler, more transparent formulations. Clean-label strategies once focused on removing additives. Today, they emphasize engineering ingredients to perform consistently with less intervention. Natural antimicrobials, enzyme-based stabilization and minimal-processing techniques become more viable when microbial loads are tightly managed. The result is a cleaner ingredient deck.

Once safety and formulation stability are predictable, producers can offer true customization— texture adjustments, tailored stability windows or packaging formats designed for specific retail environments. Customer satisfaction becomes structural rather than reactive, because customization rests on controlled safety processes and clean, dependable ingredients.

In this edition of Food Business Review, we explore how the industry is adopting a unified production model where safety, transparency and customization reinforce one another to deliver products that meet customer expectations with greater consistency.

We have also curated thought-leadership articles from industry experts, including Monty Staggs, Chief Executive Officer, SFE- Southwest Foodservice Excellence, and Jim Beauregard, Director of Research & Development, The Mennel Milling Company.

The publication also spotlights Gateway America as the cover feature, for pioneering phytosanitary irradiation for the safe transport of perishable goods and neutralizing pests and pathogens while keeping food clean, residue-free and environmentally responsible.

We hope this edition of Food Business Review helps you find the right partner for your requirements.